Straight From the Mammoth’s Mouth: Things You Want to Know About Ropes

I’m very particular about ropes, and several years ago I started using Mammut ropes. I wasn’t sponsored by Mammut, I just thought they had the best ropes and I was literally crazy about those ultralight dyneema slings they make. So I bought a bunch, and became a permanent fan. A few years later Mammut became my gear sponsor, and I discovered that Dave Furman, the hardgoods expert at Mammut, is even better than Google for finding out all the interesting (and possibly dumb, but he doesn’t seem to mind any of my questions!) things I’d always wondered about ropes. Maybe you’ve been wondering some of these things too, so this is the first post of three, with a few rope questions I asked him recently.

Thanks Dave!! 😀

FYI:

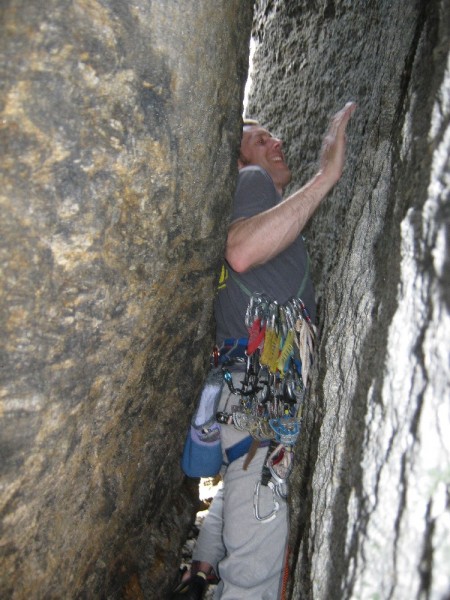

Dave Furman is the Hardgoods Category Manager at Mammut USA, where he managed to settle down and escape the life of an itinerant climber in 2001. He is a former guide and has climbed ice, rock and alpine routes on 3 continents and somewhere in the neighborhood of 25 US states and 3 Canadian provinces. He learned to climb in the Adirondacks of Northern NY in the mid 1980’s and became quite enamored of black flies, damp lichen and sub-zero temperatures—so much so that he couldn’t hack the sunshine in the Rockies and moved back east. These days his knees are starting to creak and his only claim to fame is his ability and willingness to turn tail and retreat off of any climbing route at the slightest hint of bad weather or dodgy protection.

Rope Question #1:

Do ropes have different thicknesses of sheath, and why?

Dave:

First question might be why we have multiple ropes of the same diameter that outwardly seem “the same”—what’s the difference? The answer would be that we try to look at who is using our ropes—a beginner climber who is toproping a lot vs. a sport climber who is falling a lot on very overhanging routes vs. a trad climber who is climbing lots of granite cracks vs an ice climber—and design ropes that will give them the highest level of utility combined with light weight and durability.

Since each of the above mentioned climbers tend to ask different things of their ropes, and hence they may need very different propoerties in order to stand up to one form of abuse vs another. For instance, a sport climber who is projecting hard routes is taking a zillion falls that are all relatively short—that puts a huge amount of stress on one very small section of rope, and the rope simply loses its elastic properties there and goes flat. Contrast that to the trad climber who is falling much, much less, but is usually on terrain that is less than vertical—this subjects the rope much more to abrasion of the sheath. Then there’s the ice and alpine climber who virtually never falls, but is routinely dragging the rope over sharp edges, blocky terrain, getting it wet and drying it, etc.

If we build all of our ropes to make the sport climber happy—i.e. they hold a ton of test falls for their diameter—because we need to give up some elements of the rope in order to build a rope that can hold all those falls we might disappoint the other climbers who don’t need a rope to hold so many falls, they need different things from their ropes. One of the big differences between ropes will be how climbers wear it out—if they wear it out from falling a lot, or if they wear it out from abrasion on rough rock. Although there are other elements in play that we can use to affect these properties, one of the differences in construction we use that reflects these design priorities is the relative thicknesses of the core vs the sheath—we can make two 10mm ropes, one having a thin core and thick sheath, and the other having a thick core and thin sheath. All other things being equal, the rope with the thick core and thin sheath will hold more falls before going flat, but wear faster from abrasion; and vice versa.

For instance, our Genesis 8.5mm half ropes are designed for ice and alpine climbing. Climbers rarely fall in these situations but they do subject their ropes to incredible abrasion and they need them to be very cut-resistant. With these ropes we consider a high number of test falls held to be of relatively less importance, so we sacrifice the falls-held rating—which reflects to a large degree how long a rope will last under repeated hard falls—in order to build a rope that will be ultra-durable under very harsh abrasion conditions and will be more difficult to scrape through to the core. We do this in part by altering the tension the rope is braided under, the pattern of the braid, chemical treatments that are thermally applied during the heat-treating process, etc—but we also use a relatively thin core and a very thick sheath, because that helps the rope to be as durable as possible under these types of situations.

Some of our ultra-thin single ropes like the Serenity 8.9mm have a relatively thin sheath because even with all the tricks we can muster we still need a certain amount of core in order to pass the UIAA test for a single rope—in this case we use a thinner sheath to achieve a very low weight and thin diameter, but we do thins knowing that this is a very specialized rope that is only appropriate under very specific circumstances. In these cases they are used by very experienced climbers for hard sport climbs or alpine routes where they are willing to sacrifice a level of abrasion resistance in exchange for lighter weight—this is why we recommend that people do not use any of these very thin single ropes for workout climbing or toproping. People also need to recognize that even though these are single ropes, and even though the diameter is larger than our Genesis half ropes, under conditions where the main danger is cutting or abrasion the thicker rope might actually be LESS durable and have a lower safety margin.

People who are comparing two ropes of similar diameters can usually see this in the test results—Mammut publishes the % of each ropes weight that is sheath so that people can judge for themselves what rope they will be happiest with. If you fall a lot, choose a rope with a high fall rating; if you don’t fall that much then choose a ropes with a thicker sheath (and if the manufacturer doesn’t publish that info call them and ask for it!). If you climb both abrasive rock and you fall alot, then think about how you wore out your last rope—if it went flat 10 or 15 feet from the ends, then get the rope with the high fall rating for the size and if the rope just fuzzed up to the point it felt sketchy or fat or lost its dry treatment, then concentrate on a rope with a thick sheath and a compact weave.

One thing that your readers might find helpful is the rope booklet they can download in pdf form—it contains info on the different types of ropes, what each of the tests means, some guidelines on retiring a rope, etc.

Great Post… As someone who deals w/ sales at a gym, I know that will help me a ton when working with climbers/customers

That’s really interesting! Never realised ropes can be tailored so much to a specific activity! My genesis ropes are still going strong and are the first things packed for any alpine adventures!

I find this kind of stuff pretty fascinating too…!

[…] Last month Dave Furman, Mammut USA’s hardgood expert, answered my question about sheath thickness of ropes. […]

[…] in with Dave Furman, the hardgoods manager at Mammut and my gear-expert friend. He wrote some great guest posts here already about differences between ropes, and he knows a lot about specs and the more technical […]

[…] Furman, the hardgoods category manager at Mammut USA. He’s written some extremely informative guest posts here, and he is a great source of […]