How Rock Shoes Get Made

At the beginning of this year, I made a big switch. I decided to start wearing Evolv shoes, after many years with Five Ten. It was not an easy decision: I will always love Five Ten and my friends there, and they make great shoes!

For a climber, climbing shoes are the single most important thing. Chris Sharma has become deeply involved with Evolv and with shoe design, a unique relationship which has been great for everyone, including climbers who get to wear the Shamans he created 🙂 (click on this link even if you already have Shamans, because the description is hilarious)

PETA awarded Evolv a “Proggy award” in 2005 for being the best cruelty-free outdoor shoe company. Brian, the owner of Evolv, told me “they were happy that we had the most choices for vegan rockshoes. I thanked them and told them (for full disclosure and just in case they wanted to change their mind) that we were going to add some leather models in the future, but they wanted to recognize our vegan options and emphasized the “for progress” award.”

The people at Evolv are some of the most genuine, hardworking and fun people I’ve ever met in the outdoor industry (which is a big statement) and now I have the opportunity to work directly with them to build new shoes! The last few months have been really exciting, as we started working on prototypes right away by modifying existing shoes in the Evolv line for testing in the desert.

Last week, it was time to go to the factory, and take the next step. I got a tour, and then we went right to work.

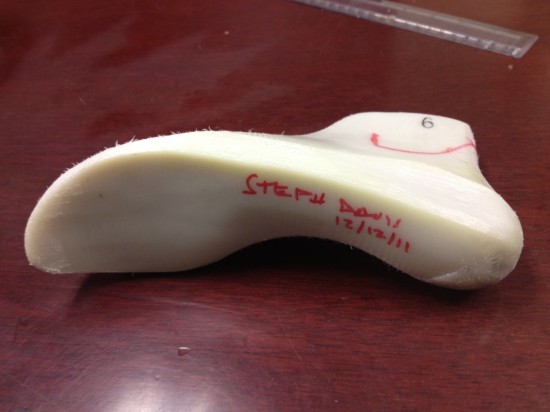

The process of building climbing shoes is really fun to see. Everything begins with the last, which is a hard plastic cast in the shape of a foot and ankle. Every single shoe style is built on a last, and the shape of the last creates the shape of the shoe. So the fleet of lasts is a very important tool for the different shoes, and shaping the lasts is where everything begins. For every style of shoe, Evolv has many lasts in each size, because a shoe stays on a last for the entire process of having the rubber applied and ground down.

Roberto Zurita is a master at last sculpting, and Chris Sharma loves this part of the process, so Chris will visit Evolv and spend days in the factory working on his own lasts. They spend hours melting plastic shavings and building up the sides of a last, and then grinding on a wheel, to make fine changes in shape.

These are some Elektras on lasts, one of Evolv’s synthetic models.

The shoes get glued, cured, and then the rand rubber is applied. Next is the sole rubber.

After the sole is on, the shoes get put into special machines to compress them and get a tight seal on the newly glued rubber.

The final step is hand grinding, to make that clean edge and brushed finish on the sole and rand.

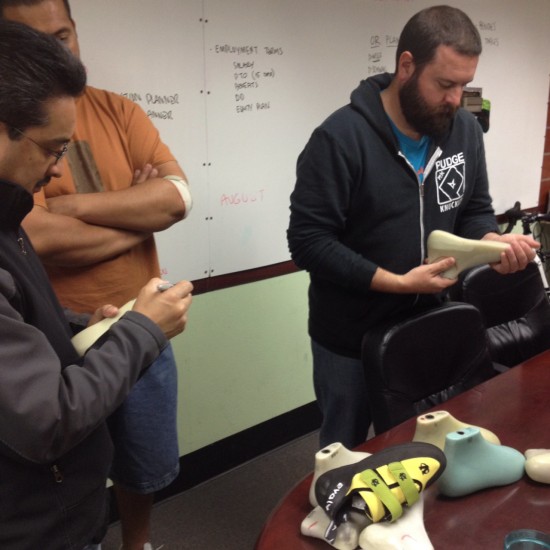

After several months of testing some protoypes and different Evolv styles, it was time to actually modify some lasts in the shape of my foot so we can work on the two types of shoes I want to make: flat (desert crack slippers) and downturned (steep climbing).

The last is the most important part of the shoe design process, so this really needs to happen with everyone together in person.

A desert crack slipper is top priority, so this was the first prototype we wanted to get into existence….we were on a tight countdown because I had an afternoon flight back to Moab.

We also had to discuss colors (fun!) and materials (the idea right now is to offer the crack slipper in both leather and synthetic, and the downturned shoe in synthetic).

Sadly, I had to leave just when Roberto had the glue on the slipper yesterday…I can’t wait to take these prototypes on their first test drive!

Wow, nice Truck! Great article, I really enjoyed it.

and the matching sticker is pretty slick!

awesome!!.. interesting report!!.. love it!!..

Thanks Steph,wonderful to learn about the people and process, who make our adventures possible .

Great Trip Report to Evolv! Pretty interesting story about how shoes are made. I am more than glad about the proggy award. I’ll be looking seriously at Evolv for a good shoe for New Hampshire granite where I climb.

So what colors are you thinking about? (This is the most important consideration, right!? 🙂 )

Maybe you’ll know this or know how to find out; why do they use black rubber on climbing shoes? It absorbs sunlight and gets blisteringly hot in no time, especially out in the desert. Couldn’t we climb in natural colored rubber?

thanks!

thanks Sujay, and I am enjoying my Bhagavad Gita 🙂

great question: I will try to find out 🙂

🙂 I am thinking sage green, for the desert.

Chris, I checked with the rubber gurus at Evolv about why all the climbing shoe companies use black rubber: here’s what they told me…

“Our high friction sole and rand rubber is made of a synthetic rubber compound combined with a carbon black filler (which makes the sole and rand black). The formulation plus processing is what makes the rand and sole sticky, crack resistant, and durable. It’s possible to use different fillers to make the rand a lighter color, but it’s best to use similar compounds to form the strongest adhesive bond between the rand and sole.”

Brian and the crew are indeed some of the nicest folks around. I have been in Evolv since its inception and will continue to do so until I can’t get em anymore. Great to have you on the team for Evolv as well. Best of luck with the shoe design and to all the great sends of 2012 and beyond.

Great post, nice photos from the Evolv at work.

Steph, I’m curious what made you switch.

Was that due to the stupid move by Five Ten to conquer new clientèle, namely

http://fiveten.com/community/blog-detail/11774-take-life-by-the-horns-with-five-ten

Personally, 5.10 move disgusted me pretty well.

Thanks!

I’m glad you liked it! I recently heard a quote, it was new to me: “He’s a friend to animals, and animals need all the friends they can get.” Thanks Mateusz for being a friend to the animals 🙂

OK, here’s a shoe design question… People either have a longer 1st (big) toe, or longer 2nd toe. Different climbing shoe manufacturers tend to designs shoes for one or the other. How important is it to match your foot with the manufacturer’s design?

Good overview, and glad to see Evolve pushing the design envelop.

It used to be that certain shoe companies were known for one or the other kind of foot. Now I’m noticing that most of them are covering both shapes with different styles. Always with shoes, performance depends on fit. You want to have the powerpoint right under the tip of your big toe for most types of climbing (pure crack is a little different, but that’s a separate topic). So if the shoe gets the powerpoint right there, it will most likely work well for you. So the good news is that now you can find shoes with almost any of the different manufacturer: the bad news is that you can’t assume that all styles from a single company are going to fit your foot. I know that with Evolv, they list the shape of the last under “specs” on the website. So if you find one that is fitting you correctly, you can immediately see which other shoes are built on the same last–I think that’s a good idea.

Anybody know anybody that makes custom shoes?

Juan

juanekelopez@gmail.com

That is one I haven’t heard of yet…

do all sponsored climbers get their own lasts?

wow! I’m glad to know about your switch.

I’m vegan too, and I’ve started climbing recently and thanks to Evolv I can have a climbing shoe without leather 😀

Best of luck to you.

Hugs from Brazil

thanks ! 🙂

Steph,

I just saw your photo with evolv in climbing magazine today and was shocked that you weren’t with FiveTen anymore and had to investigate. I have been a FiveTen customer since I first tried Mocs in a crack and have since branched out to their Anasazi line for other types of climbing. The Mocs can definitely be improved upon, but I think it will be quite hard to make a soft shoe for cracks yet be stiff enough and long lasting to be also useful on tiny edges. I’m really looking forward to trying on the end product of your experience and evolv’s shoe-making expertise, hopefully in the not-too-distant future. Good luck in your new venture!

Hello

It

was a

very excellent blog

thanks Kevin!

Juan: I have been wondering the same thing for a while because I have really hard to fit feet. However, I haven’t been able to find anyone who does yet. If you do, let me know!

I have never heard of that yet either….I think it would be a very specialized niche 🙂

I just saw the Addicts at the Hoosier Heights gym! They had all of the sizes out for people to try and buy and me being an addict (love the name – so apt!), I know I have to go back and try them tomorrow. May I ask a few questions? So if I wear size 9 in mocs (9.5 street), what size should I wear for the Addicts? Will they stretch and by how much? I was told these are pre-production models and was wondering if I should wait until they come out next year? Thanks Steph!

Hi Kevin, I have 3 pairs in 3 sizes right now, and I’m finding them to fit the same as moccs. and….I love them!

[…] Kevin, I’m glad you wrote because I have been working with Evolv since 2012 on the Addict slipper, and I’m so excited that it’s finally coming to fruition! The […]

[…] you may know, I joined Evolv in 2012 and part of our vision was to make a synthetic slipper that would work well for splitter crack […]

[…] you know that there are vegan climbing shoes? (Check them out here. Steph Davis switched from FiveTen to Evolv shoes for this reason). Or that Organic Bouldering pads are […]